Thanks to its policy that is definitely focused on technical innovation, the construction concept developed by the R&D department of Mondial Piscine is more relevant than ever before.

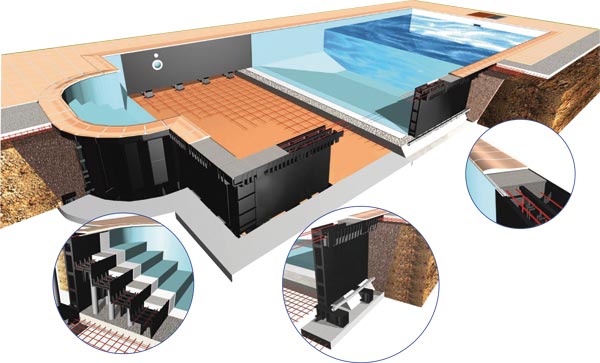

This concept consists of using shuttering panels that can be easily transported (1m wide, 1.20 m or 1.50 m high and 15 cm thick), injected on a 1700 ton press and made of polypropylene for a weight of 14 kg to set the swimming pool. These panels are designed to support concrete and have been tested to guarantee resistance of structure as well as deformation caused by frost or topographic form.

This patented concept helps construct swimming-pools completely made of "reinforced concrete".

This concept consists of using shuttering panels that can be easily transported (1m wide, 1.20 m or 1.50 m high and 15 cm thick), injected on a 1700 ton press and made of polypropylene for a weight of 14 kg to set the swimming pool. These panels are designed to support concrete and have been tested to guarantee resistance of structure as well as deformation caused by frost or topographic form.

This patented concept helps construct swimming-pools completely made of "reinforced concrete".

This process integrates many shapes of staircases (roman, right, trapezoid, oblique..) declined in various sizes and casted directly at the same time as the entire swimming pool. Thus the work consists of a homogeneous and indeformable cast solid unit. The staircase will be covered with a liner ensuring a total homogeneity of the colours of the swimming pool.

An earthwork of 20cm around the structure is possible owing to the fact that the concept does not require stay struts or material of adjustment and thus avoids the risks of cracking of the beaches caused by the compressing of a worked ground. A system of peripheral chutes ensures an immediate installation of curbstones.

The liner is firmly maintained in an extrusion anchored in the concrete structure. The liner is not likely to detach itself.

The CSTB certification Technical certification n°3/05-449

The CSTB certification Technical certification n°3/05-449

The Scientific Center of the Techniques of the Building delivered a technical certification showing that the employed technique is in conformity with the techniques of the reinforced concrete.

Strengthened by this certification and taking into account the quality of its form panels, Mondial Piscine obtained a manufacturer decennial guarantee.

An earthwork of 20cm around the structure is possible owing to the fact that the concept does not require stay struts or material of adjustment and thus avoids the risks of cracking of the beaches caused by the compressing of a worked ground. A system of peripheral chutes ensures an immediate installation of curbstones.

The liner is firmly maintained in an extrusion anchored in the concrete structure. The liner is not likely to detach itself.

The Scientific Center of the Techniques of the Building delivered a technical certification showing that the employed technique is in conformity with the techniques of the reinforced concrete.

Strengthened by this certification and taking into account the quality of its form panels, Mondial Piscine obtained a manufacturer decennial guarantee.