Saint-Gobain designs, manufactures and distributes materials and solutions which are key ingredients in the wellbeing of each of us and the future of all. The development of Crystar® ceramic membranes perfectly reflects this strategy: a filtration technology that improves recreational water quality, assures the safety of swimmers and ensures their wellbeing to the fullest.

Crystar® Filtration Technology is the product of years of R&D carried out in Germany and France. These filtration membranes are made of recrystallized silicon carbide, a special ceramic that exhibits unmatched permeability to water and excellent resistance to chemicals and abrasion. As a result, these membranes have long lifetimes and offer significant energy savings to the users.

Another key benefit of Crystar® FT is the filtrate water quality, which is close to drinking water (reduce turbidity by 40%, reduce chloramines by 40%, reduce trihalomethanes by 30% when compared to sand filters). This is all the more important in public pools, a very good medium for growth and proliferation of dangerous microbes. The reduction in chloramines makes the water less irritating for the skin and eyes, and reduces the risk of respiratory diseases for people frequently using indoor pools.

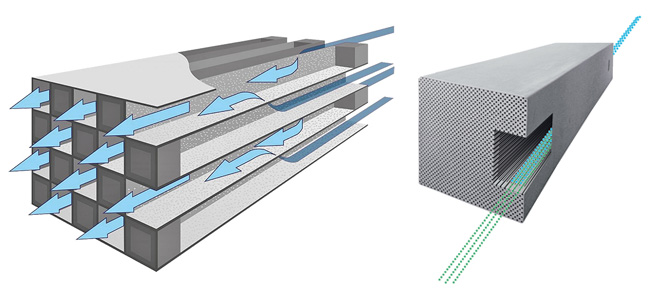

The honeycomb structure of the filtration membrane has channels alternatively plugged at inlet and outlet surfaces.

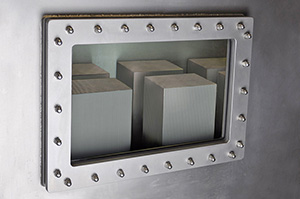

The filtration membranes have external dimensions of only 149 x 149 x 1000 mm, but provide 11 m² of filtration area thanks to to their internal honeycomb geometry. These ceramic parts are installed in housings that connect them to the filtration system.

This specific geometry allows for fast backwash cycles with low water consumption. Indeed, current users report reduction in backwash water consumption up to 70% when compared to sand filters. Only 30-60 liters are enough to clean a CRYSTAR® FT membrane.

|

With a housing (2 000 x 1 800 x 650 mm) containing 12 Crystar® HiPur membranes, a filtration capacity of 72 m3/h can be reached. With Crystar® HiFlo, the same housing will have a filtration capacity of 170 m3/h.

|

The use of a filtration medium with a well-engineered and controlled pore size ensures a superior and reliable removal of particles and microorganisms. As an example, Crystar® HiFlo membranes can remove Cryptosporidium, a dangerous and chlorine-resistant microbe, with 99.996% efficiency, according to a recent study performed at the University of North Carolina – Charlotte in the USA.

It is worth noting that the first filtration system equipped with Crystar® membranes was installed in Rödental, Germany, in 2012. During many months, the water quality of the pool was rigorously checked following the DIN norm 19643 and exceeded by far all its requirements.

Other swimming pools in Germany, Norway, Sweden and France have adopted this innovative filtration technology.

With Crystar® FT, Saint-Gobain provides pool owners with a filtration technology that lowers operational costs. Furthermore, it reduces the environmental impact (water, energy and chemicals consumption) and increases water safety for swimmers.